|

Items to have on hand for this project:

- Clutch

- Flywheel

- Throw-out bearing (usually comes with the clutch)

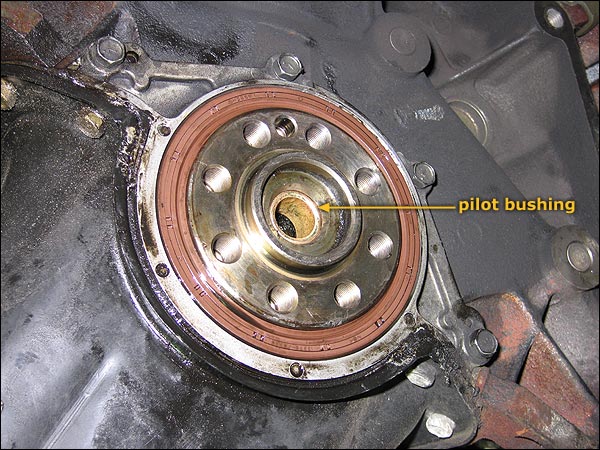

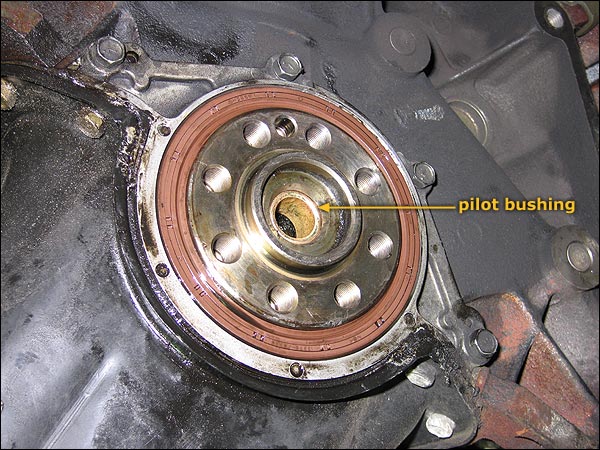

- Pilot bushing

- Rear turbo coolant hose

- Shifter bushings - you're right at these so may as well replace them. My stock plastic ones were toast and I didn't even know it.

- Turbo-to-precat/downpipe gasket on the passenger's side (I didn't disassemble the driver's side - not necessary)

- Rear main seal

- Clutch fork pivot ball

- These instructions

Make sure you have a clutch alignment tool:

And a tranny jack:

Also a seal puller if you're changing the rear main seal:

Or you can remove the whole rear oil seal retainer, but then

you'll need to have the gasket that goes behind it to replace it. Seal retainer uninstalled:

Seal retainer installed:

You can view my

collection of photos from the process.

And my

TT.net post upon successful completion.

Applicable pages in the Z32 Photo Guide:

Clutch photos

Tranny photos

Drivetrain photos

Oil seal photos

The draining coolant on the 3rd-from-bottom pic on the clutch page is

the rear coolant hose (well, where it WAS).

Clutch Replacement In A Nutshell |

|

1) Remove exhaust.

Difficulties: stubborn rusty nuts and bolts, some of which like to snap off.

2) Remove driveshaft.

3) Remove passenger precat.

Difficulties: hard-to-reach bolts, more rusty nuts and bolts that may break.

4) Remove starter.

5) Drop transmission.

Difficulties: heavy and unwieldy - help is good. Difficult to reach bolts up

top (you can't even see them - have to feel for them and then reach them with an

unbelievable contraption of long extensions and swivels).

6) Remove old clutch & flywheel.

7) Remove pilot bushing. Install new one.

Difficulties: hard to get out if you don't know the right tricks. Using

the grease-pack method*, it's a snap, and requires no cutting or chiseling.

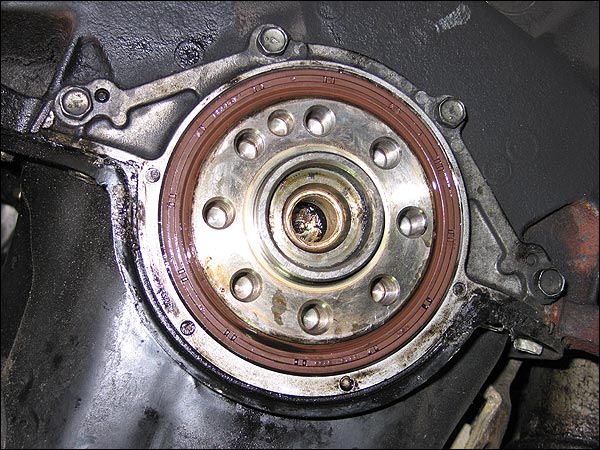

8) Remove rear main seal. Install new one.

Difficulties: very difficult to do unless you have the right tool. Go

get a seal puller. Must be very careful not to scratch sealing surface.

9) Install new flywheel & clutch.

Difficulties: if you've never done it before, getting the alignment to

be EXACT.

10) Put transmission back.

Difficulties: getting it to mate up - it likes to roll over so it seems

impossible to put back because it's running into the top of the tunnel, or

stopping two inches out from where it should and not budging. Once you get it

almost in, it likes to stop again about half an inch out, and you have to wiggle

this 85 lb chunk of metal just right. And then there's the whole process of

"stabbing" it - trying to blindly make the shaft fit perfectly into the pilot

bushing. Oh yeah, you also have to put those pesky hard-to-reach bolts back up top.

11) Putting the rest of the parts back is basically cake except for some

possible struggling here and there with the exhaust.

-----

* Grease-pack method: Shove a bunch of grease down in the center of the pilot bushing.

A LOT. Pack it in there good. Then place the tip of the clutch alignment tool in there,

and hammer it in. The grease will be packed in and have nowhere to go, and the

hydraulic pressure will force the only thing that'll move to move, pushing the

bushing out.

|